Researchs

∨Complete Recycling of Concrete Waste

∨Complete Recycling of Concrete Waste ∨Direct Bonding of Sand and Gravel

∨Direct Bonding of Sand and Gravel ∨Materials created from vegetable and fruit waste

∨Materials created from vegetable and fruit waste ∨Development of Botanical Concrete

∨Development of Botanical Concrete ∨Development of Plastic–Concrete Composite

∨Development of Plastic–Concrete Composite ∨Concrete Inspection Causing Extremely Minor Damage

∨Concrete Inspection Causing Extremely Minor Damage ∨Evaluation of Air and Water Permeation in Concrete

∨Evaluation of Air and Water Permeation in Concrete ∨Understanding of Deterioration Mechanisms of Concrete Structures

∨Understanding of Deterioration Mechanisms of Concrete StructuresComplete Recycling of Concrete Waste

Direct Bonding of Sand and Gravel

The world is running short of sand, gravel, and limestone, which are the raw materials of concrete. We are developing a new technique to direct bind sand and gravel through a catalytic reaction, without the addition of any cement paste. This technique is expected to be suitable for application in lunar bases.

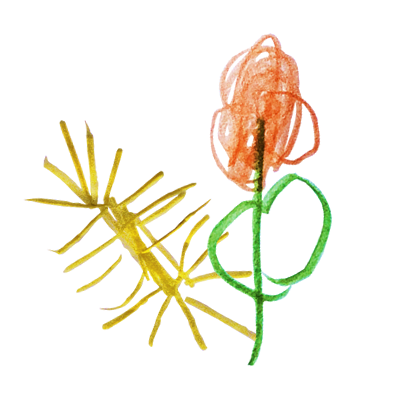

Materials created from vegetable and fruit waste

During harvesting, processing, and cooking of fruits and vegetables, plenty of inedible parts are produced. Occasionally, a large quantity of the edible part is not consumed because the size or the shape may be out of specification. Using these parts as raw materials and through the process of hot pressing, various materials have been developed that possess strength equivalent to construction materials. Furthermore, these materials have the added advantage of being edible, and can be seasoned with salt, sugar, and so on.

Development of Botanical Concrete

A new construction material was developed by crushing concrete and wood wastes and heat-pressing the obtained powder. This material is expected to show biodegradability for the crushed concrete waste is bonded by wood. Its bending strength is much higher than that of general concrete. Wood can be replaced with various plants and vegetables. This technology even enables us to produce a construction material from sand/gravel and grass.

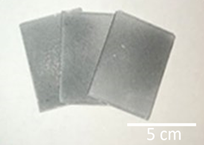

Development of Plastic–Concrete Composite

We developed a novel construction material by crushing concrete and plastic wastes and heat-pressing the resulting powder. During mechanical recycling, it is difficult to separate plastics owing to the assortment of plastics in the waste. With our technique, separation is unnecessary if a certain amount of thermoplastics is present.

The water absorption of the material can be nearly zero by optimizing the mix proportion of concrete and plastic; the resultant material is potentially more durable compared to conventional plastics. The long-term durability of the composite is currently under evaluation.

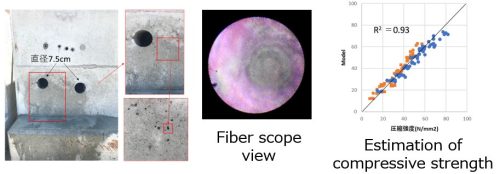

Concrete Inspection Causing Extremely Minor Damage

Concrete inspection generally requires core samples with a diameter of 10 cm, and this can cause damage to the associated concrete structures and reinforcing bars. Various semi-destructive tests and non-destructive tests have been proposed. However, the former induces concrete damage ranging in the size of a few centimeters and the latter has low accuracy. We are therefore developing novel methods for evaluating the mechanical and durability properties of concrete by drilling holes that have a diameter smaller than 1 mm.

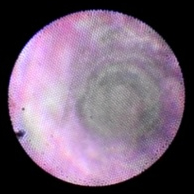

Evaluation of Air and Water Permeation in Concrete

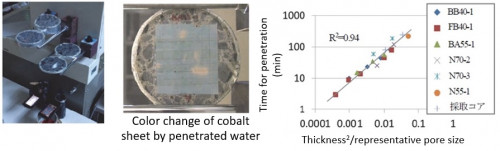

Concrete structures become deteriorated owing to the penetration of air, water, and ions.

We are therefore developing methods for evaluating such permeation behaviors based on the pore structure of concrete by conducting analysis through mercury intrusion porosimetry.

The obtained results can be incorporated in design codes for concrete structures.

Understanding of Deterioration Mechanisms of Concrete Structures

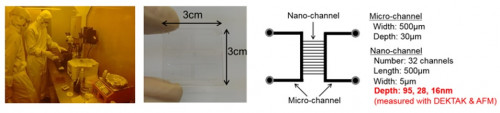

We are trying to understand the deterioration mechanisms of concrete structures due to freezing and thawing, chloride attack, etc. Model channels in the nano/microscale are utilized to observe the deterioration process in concrete.

Developing a pore structure evaluation method without mercury

Evaluating concrete pore structures is important to estimate the quality and durability of concrete. Generally, the concrete pore is analyzed using mercury intrusion porosimetry (MIP). However, with increased restrictions on the use of mercury, mercury-free pore analysis methods are necessary. We propose a new method to evaluate the concrete pore using nano-sized particles.

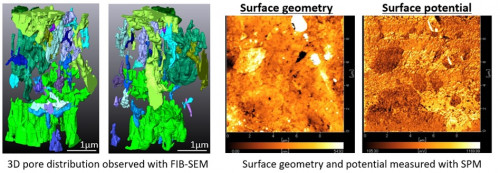

Observation and Analysis of Concrete using Special Devices

To understand and evaluate concrete properties, we used various special devices, such as Focused Ion beam-Scanning Electron Microscopy (FIB-SEM) to observe the three-dimensional pore structure of concrete; Scanning Probe Microscopy (SPM) to measure microscopic surface property; and Magnetic Resonance Imaging (MRI) to observe water permeation into concrete in a non-destructive way.

Development of evaluation methods for concrete properties

Many methods to evaluate the mechanical performance and durability of concrete have been proposed. However, limitations such as damage to concrete, accuracy, cost, and portability exist. We develop new methods to evaluate the various concrete properties to solve the aforementioned problems

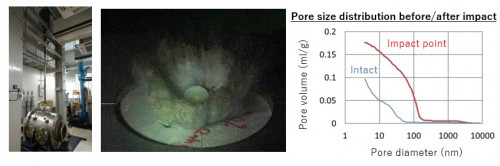

High-speed Impact Test

Accidents caused by explosions and terrorism may lead to high-speed impacts on concrete. Although macroscopic fracture mechanisms such as crack propagation have been studied, the microscopic effect of impact on the cement paste matrix is not well known. Our primary objective is to employ a gas gun for conducting high-speed impacts on concrete and thereby analyze the impact points for studying the changes in the cement paste matrix. We are currently collaborating with an impact engineering laboratory for the same.

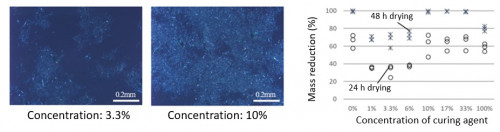

Water Evaporation Reduction Mechanism by Curing Agents

Curing agents are employed for retaining moisture in concrete, but moisture retention can vary according to prevalent conditions. Since the evaporation reduction mechanism of curing agents is not well known, we are studying it for effective usage. We are currently collaborating with several organic chemistry laboratories for the same.

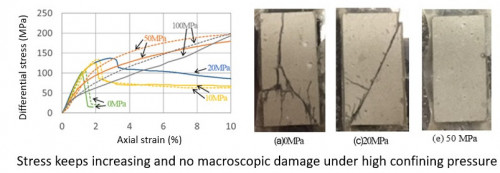

Deformation Mechanism of Concrete

Hardened cement paste is generally very brittle. However, we observed that it shows large deformation without macroscopic damage under confining pressure, and we are trying to understand this mechanism. We are working on this topic with the cooperation of geoscience laboratories.